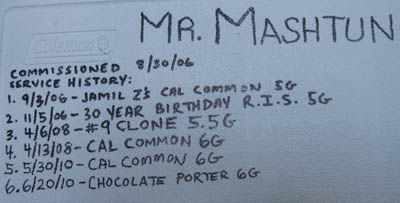

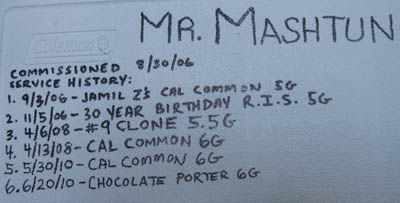

Mr. Mashtun

If you’ve been keeping up with the blog, you know I’ve been trying my hardest to pin down efficiency losses in my system. I started keeping meticulous records on water in and wort out numbers, going as far as weighing the liquid to be as accurate as possible. When my

last brew session clocked in with an efficiency in the mid-50’s, I decided to try changing my mill.

Up until now, I’ve been milling my grain with a Corona (aka Victoria) mill. This is a cheap mill made for grinding corn into flour for tortillas, not necessarily for crushing malt for brewing. There are some die-hard Corona mill supporters out there, claiming they can regularly get in the 80% efficiency range, but I never felt it gave me a good crush. In my experience, it was horribly imprecise, either spitting out uncracked grain or pulverizing both husk and kernel into flour. Add to that the small hopper and manual hand-crank operation, and it was time for a change (yes, you can motorize the Corona fairly easily, but I didn’t think it was worth the effort). I’m not doubting that people get good results with the Corona, but for me, it was too little, too late.

I did a bit of research, and wound up ordering a Barley Crusher mill. This is a highly rated, fairly inexpensive grain mill with two knurled steel rollers designed especially for brewing. I took advantage of the discount pricing BeerSmith is offering and ordered the 15 pound hopper model for $154 (with shipping). When the mill arrived this week, I was excited to try it out for this weekend’s brew.

In a word: amazing. The Barley Crusher took a little adjusting to – I ran a half pound of grain through to break it in, per the instructions, with no issues. Using a power drill which easily attached to the crank, it took about three seconds. However, when I loaded the hopper with 10 pounds of pale malt, the rollers wouldn’t grab the grain and just spun uselessly. A quick search online showed this isn’t an uncommon problem, but one that is easily solved – by loading the hopper with one scoop of grain first, I was able to “prime” the rollers and once they caught, I was free to load the hopper to capacity.

What would have taken me the better part of an hour with the Corona took no more than three minutes with my DeWalt drill and the Barley Crusher. More importantly, however, was the look of the crush – the kernels were all cracked nicely, but the husks were still intact – perfect for setting a filter bed in the mashtun. I crossed my fingers, hoping this would boost my numbers a bit.

I noticed a difference during sparging and lautering – my wort ran clear faster, and I had no hint of a stuck sparge. I measured my pre-boil efficiency and came out over 75% – about a 20% boost just from changing one piece of equipment! Now, my brewhouse efficiency (true efficieny, into the fermentor) dropped quite a bit, but that was due to excess wort losses – I had trouble racking into the fermentor due to a clogged bazooka screen in the kettle (using whole leaf hops without a hop bag = dumb). At the end of the brew, I clocked in at 5 gallons of 1.060 OG wort when I was expecting 6 gallons of 1.061. The volume difference killed my brewhouse efficiency, but my recipe was calculated at an estimate of 70%, so it all balanced out in the end. I’m happy – my last brew came in 18 points under gravity, so this is a major improvement!

I will keep chasing my numbers and reporting back here – if I want to start formulating my own recipes and brewing to consistency, I need to dial in my system exactly. That means getting good sugar extraction from my mash, figuring oiut my evaporation rate, and determining exactly how much water/wort is lost to grain absorbtion and tun/kettle deadspace.

The Chocolate Porter is in the fermentor happily bubbling away (at 68°F, innoculated with the WL San Francisco Lager yeast I cultured from the last batch). I used my new Thomas Fawcett & Sons Halcyon pale malt as the base, and I am expecting nothing short of greatness from this batch! I am also proud to announce that during the mash, I grilled up some traditional Wisconsin-style bratwurst. Below is a picture of them simmering in beer and onions before moving to the grill.

Simmering bratwurst

The wort sample from the porter tasted dead on, the bratwurst were delicious on a toasted hero with raw onion and brown mustard, and it made slaving away over propane burners in the sweltering heat worth it. Nothing says summer like mixing a brewday with some grilling! Next week, I hope to knock out a new version of the California Common recipe while smoking some of my (semi)famous pulled pork. Speaking of smoking, I have plans to smoke some grain to create a cherry-smoked Hefeweizen and a classic Bamberg Rauchbier.

Tell me about your most recent brewday, your battles with efficiency, and your favorite sausages!

Coming soon, on lootcorp: my new chest freezer, why new beer site BrewAdvice.com needs our help, how to wire up a Ranco temperature controller and save some money, and lootcorp.com’s very first iPhone app!

Prost!

Well, it was bound to happen eventually.

Well, it was bound to happen eventually. The good news: I now have ten gallons of Kölsch fermenting in my chest freezer (which just BARELY fits two 6.5G plastic buckets inside).

The good news: I now have ten gallons of Kölsch fermenting in my chest freezer (which just BARELY fits two 6.5G plastic buckets inside).