The beginning of the brewday went very slowly – I had to do a lot of cleaning and prep work since my brewery had sat dormant for so long. After a few hours of getting organized, washing equipment, and grinding grain, I was ready to mash in. I was using my recipe for Engine 97 Steam Beer, which calls for mashing at 154°F for one hour. I stirred and measured the mash temperature every 15 minutes.

I batch sparged and wound up with a little over 10 gallons of wort. I had measured my water in and out of the mash very carefully (using a scale to weigh it) since I am trying to lock down the loss numbers for my system. This brew lost appx. 1.5 gallons to grain absorption and another half gallon or so to tun deadspace. These numbers were a bit off from my assumptions, and this (along with poor efficiency) caused me to miss my OG by quite a bit. During the next brew, I will try and pin down my efficiency problems, although I have a suspicion that my Corona mill is to blame.

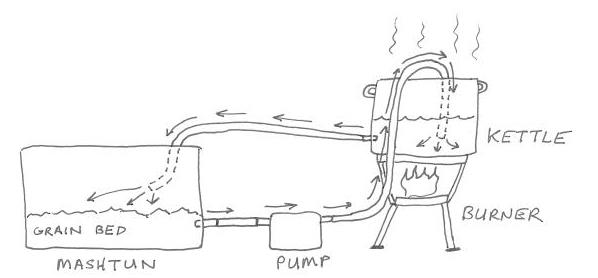

After the mash was complete, I transferred the wort to the kettle for boiling. Everything from here on in was pretty textbook – 90 minute boil, with hops additions at 60m, 15m, and flameout (all Northern Brewer pellets).

I set up for chilling by adding the IC to the boil with 20m remaining, along with a Whirfloc tablet. I also started recirculating wort through my March pump to sanitize it. The pump is great – it allows me to chill faster by moving the wort around the chiller in the kettle, and then lets me transfer to the fermentor with ease.

I chilled down to about 68°F (took about 20 minutes), racked to the primary, and added the yeast. Set it up in the fermentation fridge to ferment around 58°F. There was airlock activity within 24 hours, and the beer is now happily bubbling away.

I wound up with an OG of 1.042 (reading taken before adding the starter wort) – my target was 1.055 or so, so this is going to be a bit lighter beer than intended. I wound up with an efficiency of around 55%. I’ll need a few more brew sessions of data before I can really figure out where my losses are occuring, but I am tempted to try the same recipe with malt milled at the homebrew shop to see if I get a big jump. I have a love/hate relationship with my Corona mill, but I just don’t know if it is consistent enough to get a good crush. Seems I am either getting uncracked kernels or flour, and it is very hard to find that middle ground.

I will be using this batch’s yeast cake to brew another few batches of this beer – I have been told the yeast doesn’t reach its peak until the third batch or so. Hopefully I’ll be able to get my system dialed in and have a perfect batch of California Common by that third time around.