It’s been awhile.

Don’t look at me like that… It’s not like I’ve been out there winning beer competitions and brewing barrel after barrel of delicious homebrew while deliberately leaving you out of the loop.

Nah, man, it’s more like I lost my mojo. I gave up. I had a few false starts and would make some beer, but my heart wasn’t really in it and it didn’t take much to get me to cancel a brewday.

I have a refrigerator full of old yeast, a freezer full of hops pellets, and some old recipe kits I haven’t done anything with. My equipment sits unused and dusty. All remnants of what used to be a very fun hobby.

But, wait! For the first time in a long time, I actually want to brew again! I have ingredients on order for a batch this weekend and a bunch of new equipment I’m dying to break in.

The Hammer bought me some awesome stainless steel gear last year. The first item is the SS Brewtech Brew Bucket fermentor (Brewmaster Edition). I’m really stoked about this little guy — it replaces the lousy plastic buckets I’ve been using forever, the ones with the lids that have nooks and crannies you can never get the dried krausen out of. The ones I have to keep replacing over and over again. Finally, I have a real fermentor — easy to clean, easy to sanitize, racking arm, conical bottom for trub/yeast collection, and a thermowell I can use with my temperature controller’s probe to get better fermentation control.

It’s just small enough to fit into my fermentation fridge, so I don’t need to change anything as far as that goes. Really looking forward to using this for the first time!

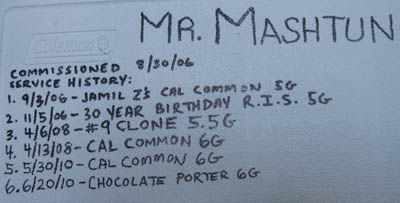

The second awesome gift was a SS Brewtech 10G InfusSion mashtun. Again, this is replacing old plastic — however, this time, it’s bittersweet, because it’s my old friend Mr. Mashtun who is being put out to pasture.

Mr. Mashtun

That’s right, Mr. Mashtun, made with my own two hands, along with two additional hands of my dad, commissioned way the f back in 2006, is retiring. I will never forget his service and his contribution to my progression into all grain brewing. However, when I look at what the future holds I can’t deny that we are making some serious progress here…

I’m really excited to see what impact this new mashtun has on my efficiency numbers…I’ll still be batch sparging for the time being, but this might even get me experimenting with fly sparging. SS Brewtech makes a pretty nice add-on sparge arm, but I’m going to wait until I have a few brews under my belt first.

I’ll be brewing up an old favorite, the Engine 97 Steam Beer I adapted from Jamil Zainasheff’s famous California Common recipe. Wish me luck, and hopefully I’ll be seeing you around here a little more often.