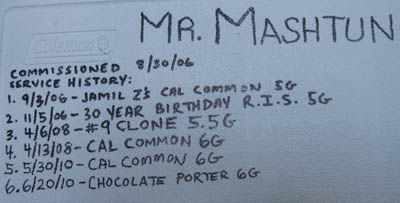

My trusty assistant

I’m a big fan of witbiers – they are nice and refreshing on a hot day and are also great bridge beers you can use to expose your macroswill-chugging friends to craft beer without scaring them off. There’s a delicate balance that makes this a challenging brew to pull off correctly. The beer is supposed to have a touch of sweetness (usually present as honey or vanilla notes), moderate citrus fruitiness, some spicy, peppery notes, and a very slight lactic bite in the finish. If any one of these flavors becomes too dominant, the beer will lose the refreshing crispness that wits are known for. Witbiers should also have a somewhat creamy, smooth mouthfeel from the use of wheat and oats in the mash.

Mashing in the kettle

The recipe I used called for:

- 5.5# of Pils malt

- 5# flaked wheat

- 2# flaked oats

- 0.25# Munich malt

- 1.2oz Hallertau hops @ 60 min

- 43g citrus zest

- 11g cracked coriander seeds

- 1g dried chamomile flowers

You don’t need to grind flaked wheat and oats, but I threw them in the mill because I’ve heard of slight increases in efficiency when doing so. I mashed in my kettle, since this was a step mash and it’s much easier to do those with direct heat. I used a protein rest at around 124°F for 20 min or so and then brought the temp up to 158°F. The problem with mashing in my kettle is that it loses heat very quickly. I had to fire the burner several times over the mash to keep the temp up, and in reality it fluctuated anywhere between 160°F and 153°F. It spent the bulk of the time in the 156-159°F range, so hopefully there will be no ill effects on the finished product.

I tried a new technique this time – iodine testing for starch conversion. Basically, you buy a bottle of tincture of iodine (available at any pharmacy) and use it to test your mash. Extract a small sample of mash liquid (there should be no grain particles in the sample) in a bowl or something and add a drop of iodine – if it turns black, conversion is not complete. If it stays tan/reddish, you are good to go. My recipe called for a 90 minute mash due to all of the wheat and oats, but testing at 60 minutes showed conversion was done so I mashed out at 168°F. I then added about a half pound of rice hulls to help avoid a stuck sparge.

Hallertau hops and citrus zest

I nailed my pre-boil target exactly – 7G of wort @ 1.042 SG. The rest of the brew went very well, except for one mistake – I miscalculated my evaporation rate. I had been doing 60 minute boils and forgot to compensate for the fact that I was using a 90 minute boil for this recipe. Stupid mistake, and I paid the price. What should have been 5.5G of 1.050 SG wort turned out to be ~4.75G of 1.069 SG wort!!

Well…I made two mistakes here. First was not compensating properly for the longer boil. Second was not testing the gravity during the boil. If I had been keeping an eye on things, I could have added water or reduced the boil time to compensate. However, if I’m going to miss on gravity, I always prefer missing to the upside. When my beers miss high, I just throw the “imperial” tag on them and call it a day!

Highlight of the brewday had to be the last five minutes of the boil, when I added in the citrus zest, the chamomile, and the coriander – the wort smelled amazing! I didn’ have time to make a yeast starter for this brew, so I pitched two packs of Wyeast 3944 (Belgian Witbier). Not very cost effective, but the right thing to do in the absence of a proper starter.

All in all, it was a good day and a good brew – I just hope the higher alcohol content doesn’t wreck the balance of the beer. I’ll keep you posted!

The good news: I now have ten gallons of Kölsch fermenting in my chest freezer (which just BARELY fits two 6.5G plastic buckets inside).

The good news: I now have ten gallons of Kölsch fermenting in my chest freezer (which just BARELY fits two 6.5G plastic buckets inside).